Not known Factual Statements About precision machining

Any time you design a part, it’s as vital to think about wall thickness as the beauty of the design.

In these many years, Brown & Sharpe as well as the Cincinnati Milling Machine Business dominated the milling equipment discipline. On the other hand, many other corporations also created milling machines at some time, and several ended up considerable in several techniques. Other than lots of specialised output devices, the archetypal multipurpose milling machine with the late nineteenth and early twentieth centuries was a large knee-and-column horizontal-spindle style and design with energy table feeds, indexing head, as well as a stout overarm to support the arbor.

This milling equipment was extended credited to Eli Whitney and dated to circa 1818. From your 1910s through the 1940s, this Model of its provenance was commonly published.

Facts About precision machining Revealed

The deal with milling process can in theory deliver very flat surfaces. Even so, in observe the result often shows obvious trochoidal marks adhering to the movement of details around the cutter's conclusion deal with. These revolution marks provide the characteristic complete of a deal with milled floor. Revolution marks may have major roughness according to variables which include flatness of your cutter's conclude experience along with the degree of perpendicularity amongst the cutter's rotation axis and feed course.

e., the axes that we now get in touch with XYZ) a lot more elegantly than had been accomplished up to now, and it authorized to the milling of spirals applying an indexing head fed in coordination With all the table feed. The term "common" was applied to it since it was Prepared for virtually any get the job done, such as toolroom do the job, and was not as constrained in software as earlier patterns. (Howe had intended a "universal miller" in 1852, but Brown's of 1861 will be the 1 thought of a groundbreaking achievements.)[26]

In tedious, a Software with an individual bent pointed idea is advanced right into a roughly created gap in a spinning workpiece to a little enlarge the hole and boost its precision. It is a fantastic ending Procedure Employed in the final stages of product or service manufacture.

They are utilized to mill grooves and slots. Basic mills are utilized to condition flat surfaces. Many cutters may be ganged jointly over the arbor to mill a complex shape of slots and planes. Unique cutters may Slash grooves, bevels, radii, or in fact any segment sought after. These specialty cutters tend to be pricey. Simplex mills have one particular spindle, and duplex mills have two. Additionally it is easier to Slash gears on the horizontal mill. Some horizontal milling machines are Geared up with an influence-just take-off provision over the desk. This allows the table feed being synchronized into a rotary fixture, enabling the milling of spiral characteristics for example hypoid gears. Comparative deserves[edit]

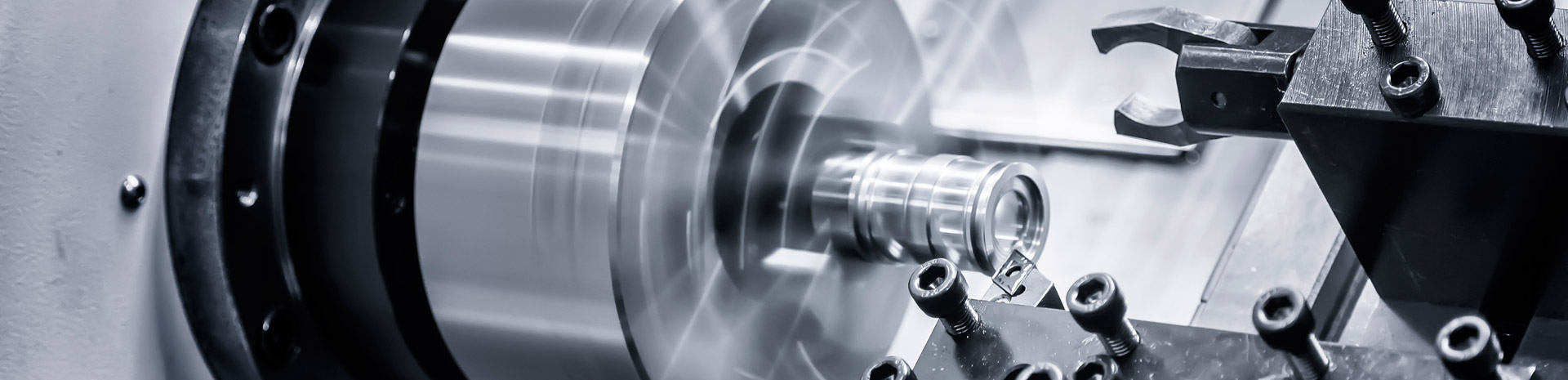

The mixing of milling into turning environments, and vice versa, commenced with Stay tooling for lathes plus the occasional utilization of mills for turning operations.

machining Options

Regarding annual pounds put in, machining is the most important in the producing procedures. Machining can be outlined as the whole process of removing materials from the workpiece in the form of chips. The term metallic slicing is applied when the material is metallic.

NC and CNC's drastic improvement of machine Instrument Management deeply transformed the lifestyle of producing.[31] The details (which can be past the scope of this article) have progressed immensely with each and every passing decade. nineteen eighties–present[edit]

With our prototype services we Establish the bridge between the planet of Strategies usinagem plus the shipping of solutions

Drilling functions are operations wherein holes are generated or refined by bringing a rotating cutter with reducing edges for the reduce extremity into connection with the workpiece. Drilling operations are performed generally in drill presses but from time to time on lathes or mills.

The best Side of machining

CNC Industries wholeheartedly agrees that information and facts administration is crucial to an organization’s accomplishment. Their information and facts program has saved them countless hours and has facilitated virtually perfect On-time Shipping and delivery and High-quality functionality.